What is Roller chain coupling?

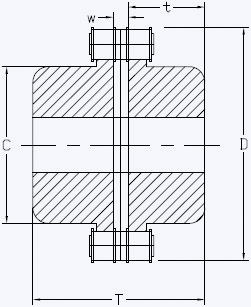

A roller chain coupling is mechanical equipment composed of a double-strand roller chain and two forged, extended, hardened sprockets.

Cast Aluminium Covers

For more demanding applications, cast aluminium covers extend life of couplings by providing continuous lubrication and full protection from abrasive elements. The two halves fit around the coupling and connect by ‘Nyloc’ cap-head bolts. Neoprene seals are fitted to seal between sprocket hub and cover. These covers are fitted after coupling is fully installed on shafts.

The design is simple and highly effective. Despite chain couplers small size, it is composed of a robust chain and specially cut and hardened-tooth sprockets that permit a high amount of torque to be transmitted.

Roller chain coupling consists of six basic components:

- Pin

- Bushing

- Roller

- Pin link plate

- Roller link plate

- Forged harden sprocket hub

Each of these components of chain couplers are manufactured and assembled to precise tolerances and heat treated to optimize performance with regard to wear resistance, fatigue strength, and tensile strength of chain couplers.

Key Features of Roller Chain Coupling

- The single-pin design permits the chain to be uninstalled and reinstalled quickly and efficiently, reducing labor needs and minimizing downtime

- Roller chains are manufactured like a usual chain structure. It is a series of cylindrical rollers connected by links.

- A rotating sprocket which is connected to the motor moves the chain, while the other end of the chain couplers can then be connected to some part of the load.

- Roller chain couplings are uncomplicated but provide a compact and flexible coupling that is suitable for an extremely wide range of applications

- Due to its design its torque is spread throughout the roller chain and the entire device. This is why there is an even amount of torque distributed throughout the coupler when in motion.

- The sprockets and chain couplers produce a slight clearance, which is why absolute shaft alignment is not required for the coupling to function. (However, it is highly recommended to have the shafts completely aligned if possible)

Applications of roller chain coupling

- Chain couplings are used in transmission of power between two shafts

- Chain couplings are normally efficient for low speed and high torque applications

- Chain couplers are used in misalignment between shafts

- Chain couplings are considered a cost-effective way to transmit power between shafts

- Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power

- Used in domestic, industrial and agricultural machinery

- Used in conveyors

- Used in wire- and tube-drawing machines

- Used in printing presses , press machine etc

Compact and Powerful

Safe and Smart

Easy Alignment

Selection of the Size of the couplings

For 8 to 16 hrs/day service use next step service factor. For 16 to 24 hours/day service use service factor two step higher loading.

- Multiply horsepower of driver unit by the service factor. This is design horsepower.

- Note the maximum rpm. at which the unit will run and its shaft diameter.

- From H.P. rating table select the coupling size which is rated equal to or slightly greater than design H.P. required at the rpm. at which the coupling is to operate.

- Also make sure that the diameter at the shaft is less than the maximum bore permissible on the coupling. If the coupling is not large enough to accommodate the shaft size, use the next coupling which can be bored to suit the shaft requirement.

H. P. Ratings

Lubrication