Servo Encoder Couplings are important in achieving precision, accuracy, and reliability in a variety of mechanical systems, making them a key component when it comes to motion control and automation.

What is an Servo Encoder Coupling?

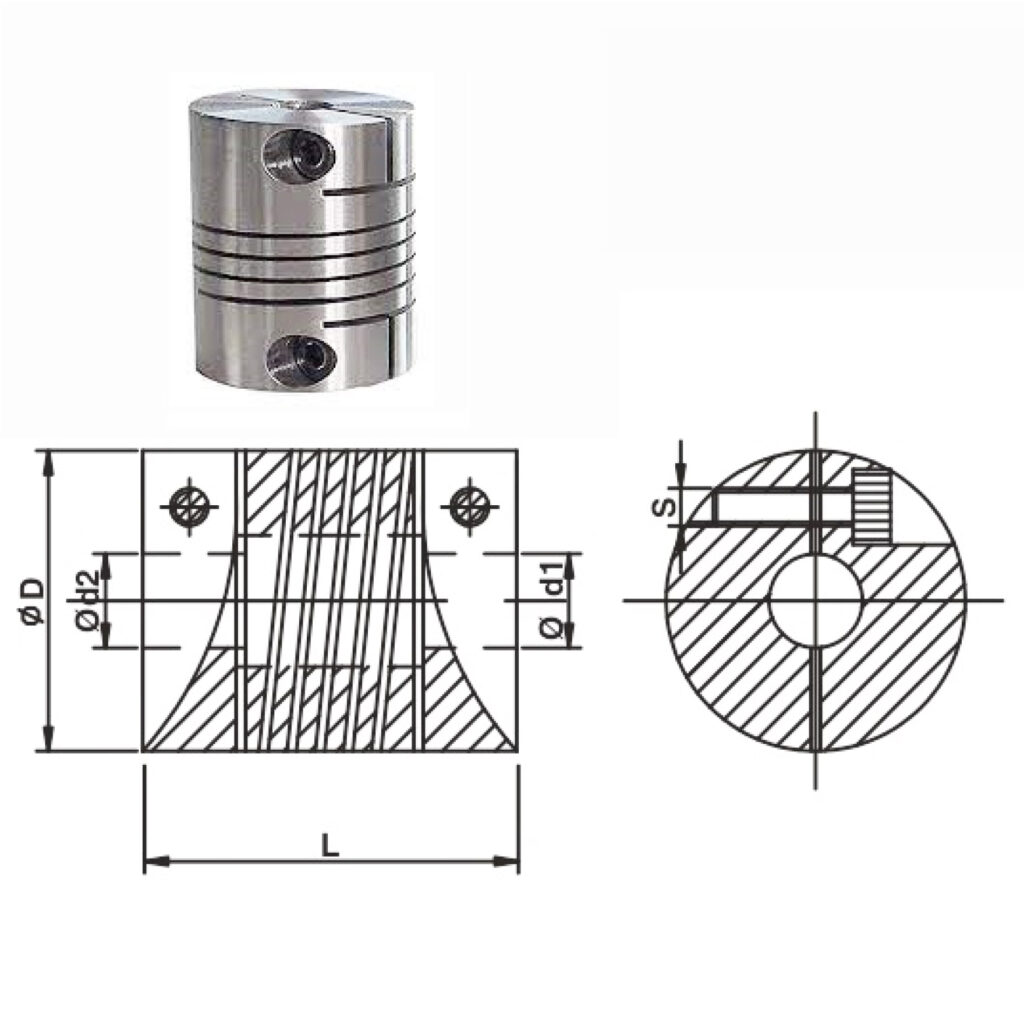

An Servo Encoder Coupling is a shaft coupling that connects two shafts to transmit torque, motion etc. It is a critical component in mechanical systems designed to connect and synchronize rotating shafts while accommodating misalignments. This It is a coupling which can adjust itself to misalignment of two shafts connected by it. Misalignment may be angular, parallel or skew.

Types of Servo Encoder Couplings

● Flexible Disc Couplings

● Bellows Couplings

● Beam Couplings

● Double-Loop Type Coupling

● Oldham Couplings

Key Features of Servo Encoder Couplings

Precision Alignment

Servo Encoder Couplings offer precise shaft alignment, ensuring accurate transmission of rotational motion and minimizing wear on connected components.

Torsional Flexibility

The ability to handle angular and parallel misalignments provides torsional flexibility, reducing stresson the system and enhancing its longevity.

Zero Backlash

The ability to handle angular and parallel misalignments provides torsional flexibility, reducing stresson the system and enhancing its longevity.

Vibration Damping

Certain types of Servo Encoder Couplings incorporate features for vibration damping, contributing to smoother operation and increased system reliability.

High Torque Transmission

Servo Encoder Couplings offer precise shaft alignment, ensuring accurate transmission of rotational motion and minimizing wear on connected components.

Applications of Servo Encoder Couplings

- Motion Control Systems

- CNC machinery

- Industrial Automation

- Applied in conveyors

- Material handling equipment

- Processing machinery

- Medical Devices

- Aerospace Industry